Introduction

Taiwan Casting Industry Association (TCIA) was founded on July 22, 1995. TCIA provides help to all 300 members to deal with casting related business and foundry management. TCIA also provides information and guidance to Taiwan government and takes part in government economic programs.

Industry Characteristics

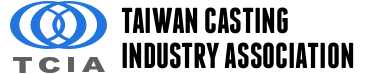

The foundry industry is a traditional and ancient field that encompasses various theoretical and technical aspects, constituting a fundamental part of a country's industrial base and interconnected with numerous industries. Casting products have a wide range of applications across industries such as defense, medicine, steel, cement, petrochemicals, water resources, power generation, shipbuilding, electronics, machinery, civil engineering, and more. Everyday items like automotive components, consumer goods, leisure and sports equipment, as well as electronic components in the realm of 3C (computers, communications, and consumer electronics), all owe their existence to casting, highlighting its pivotal role in the industrial chain, which cannot be overlooked.

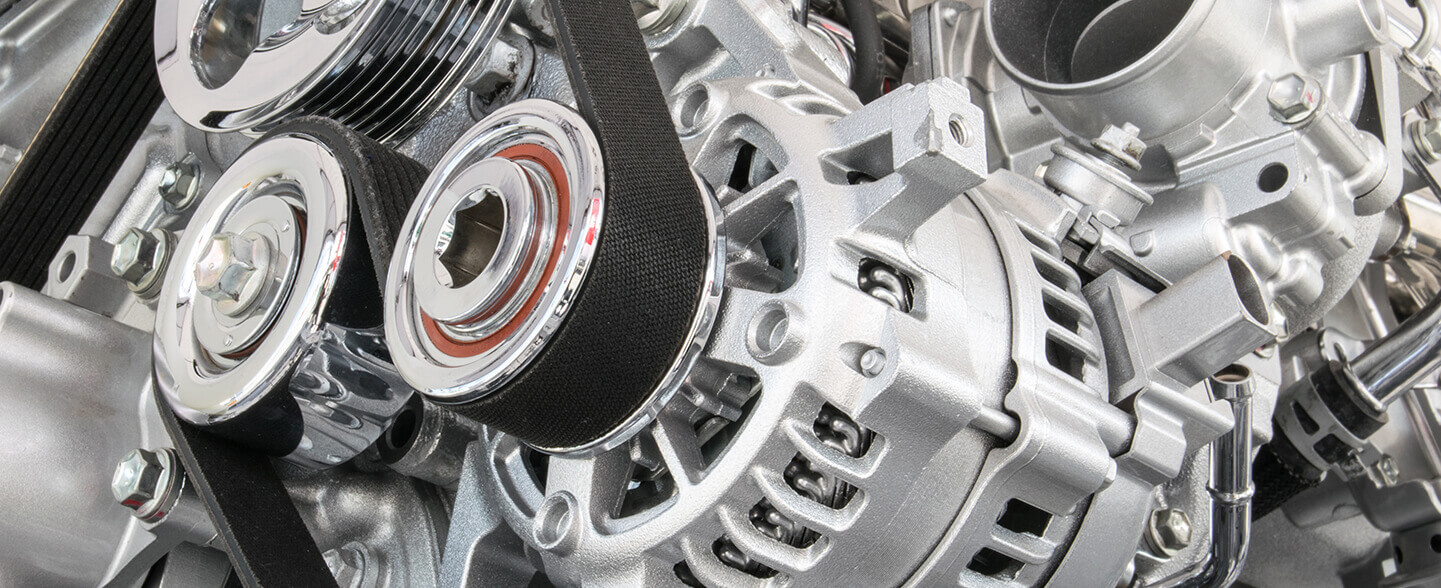

The Taiwanese foundry industry, after decades of diligent efforts, has achieved an annual production capacity of approximately 1.4 million tons, ranking twelfth globally, with a production value of 90 billion Taiwanese dollars. It is progressing towards automation in production and digitalization in business operations. The establishment of an industry network primarily composed of small and medium-sized enterprises has been a focus. Through the integration and communication facilitated by associations, this network covers all facets of casting product manufacturing, including various materials (titanium and superalloys, steel, iron, aluminum, copper, magnesium, zinc alloys) and casting processes (large-scale sand molding, semi-automatic molding, fully automatic molding, precision investment casting, centrifugal casting, die casting, and low-pressure casting), as well as product types (castings, machined components, complete sets of machinery) and production modes (large, medium, and small-sized castings, diverse small-batch and large-scale production). These SMEs exhibit flexibility and adaptability in their operations. Leveraging rich knowledge, experience, and intellectual resources from both domestic and international circulation, coupled with a comprehensive collaborative industrial system, Taiwan can ensure balance and excellence in product production timing, quality, and pricing. This enables the overcoming of inherent disadvantages such as the lack of natural resources, labor shortages, and stringent environmental regulations, allowing the industry to compete internationally for orders and meet both domestic and international demand for castings.

SERVICES OFFERED

Consultation and service of common interests for all members.

Dissemination of government regulations and exchange of viewpoints amongst members themselves.

Exhibits and visits arrangement held both in Taiwan and abroad.

Editing and publishing of "Castings Bulletin".